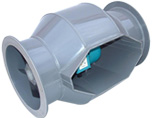

As the dust laden air enters the dust collector housing through the inlet duct, the baffle plate located inside of the inlet act as a pre-filter and prevents re-entrainment by guiding the gas stream downward uniformly. The baffle plate deflector directs the heavier dust particles into the hopper. The remaining lighter dust particles are drawn against the outer surface of the filter bags where they are retained. Clean air passes through the filter bags and leaves the clean air chamber through an outlet duct.

As dust accumulate on the filter bags, periodic cleaning of the bags are important in order to maintain continuous operation. This periodic cleaning of bags is achieved by introduction of timed, momentary pulse of compress air through a specially designed blow pipe with nozzles mounted above each filter bag. Only a portion of the filter bags are cleaned at one time, allowing the remaining filter bags to continue their filtering action.

We are manufacturer of pulse jet dust collection system for various industries requirement for air quality improvement and enhancing the quality of air released by collecting dust and other impurities from air or gas by removing particulate matter from the air and environment. We are a manufacturer of highly customized units to accurately match your Application requirements with customized ducting solutions along with our dust collectors for your specific dust collection requirements.

The dirty or contaminated air enters the dust collector through the inlet and passes through a number of filter cartridges/Bags (before the contaminated Air passes through the Filter Bag/Cartridge; baffle plate works as a protecting layer to control/retain heavy particles, which protects filter bags/cartridges to get in touch with heavy particles and damage caused by it) which retain the dust particles on the exterior surface while allowing clean air to pass through the outlet. As the collector operates, the collected dust begins to form dust cake, which eventually diminishes the porosity of the filter cartridges. As the pressure drop increases the ventilation volume of the collector decreases.